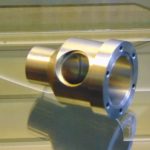

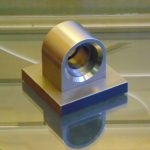

CNC Milling and Turning Solutions Offer Several Unique Benefits

Small Parts Vietnam maintains a full complement of Mazak CNC milling and turning equipment to manufacture a wide range of prototypes and parts. This manufacturing process offers several unique benefits, including:

- Cost-effectiveness: Less required labor and minimal waste help maintain costs.

- Accuracy and Uniformity: Computer controls ensure precision and repeatable quality.

- Efficiency: Automation increases the speed of manufacturing and produces faster turnaround times.

- Scalability: Carefully engineered and stored setups allow for flexible machining capacities.

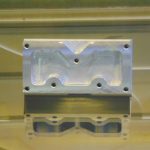

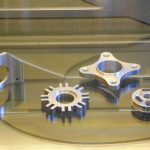

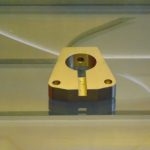

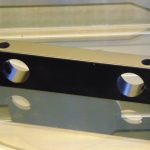

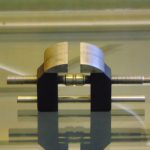

Milled and Turned Materials

To produce the right component with the ideal properties using the optimum process, we work with a variety of metal and plastic materials, including:

- Several grades of alloy and stainless steel: Parts machined from these materials exhibit high strength and corrosion resistance and are highly weldable.

- Low and medium carbon: Parts machined from these materials are highly weldable and can be hardened.

- Nylon, Teflon, PVC, HDPE, and various plastics: Parts machined from these materials have varying levels of impact strength and finish characteristics.

- Multiple grades of aluminum: Parts machined from these materials are highly machinable, achieving optimum strength with low weight.

- Common copper and brass types: Parts machined from these materials exhibit both corrosion and chemical resistance as well as high density and strength.

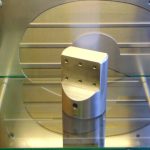

Typical CNC Machining Applications

Our team of skilled engineers and machinists employs a variety of vertical milling and turning techniques to manufacture products across a wide range of industries. For example:

- Aerospace: cabin latches, connectors, standoffs, all other NFC components

- Medical: thoracic components, graph tools, stent mandrels, hearing aid parts

- Telecommunications: antenna components, marine radio, sonar parts

- Automotive: shafts, flywheels, pulleys, adapters, connectors, fillers, caps, brackets

- Electronics: heat sinks, support brackets, sub-plates, control panels

- Military: bolts, spacers, pendant control housings, optics housings, studs, screws

- Forestry: gib screws, impact sockets, planar components, mill repair

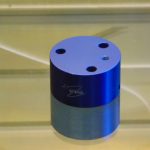

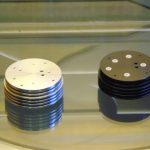

CNC Turning Equipment

Our CNC Turning equipment includes:

- 1 Miyano BNC 34-T 3 Axis w/sub turret (1⅝” cap)

- 1 Mazak QT15 w/ Hydrobar (2″ cap)

- 1 Mazak QT8 w/Hydrobar (1⅝ ″ cap)

- 2 Mazak QT8 (Chucker 1⅝ ″ cap)

- 1 Mazak Super Quick Turn 30 (4″ cap)

- 1 Mazak Nexus 250 Long Bed w/Hydrobar (3″ cap x 36” max length)

- 1 Mazak QT20 (Chucker 4” cap)

- 1 Mazak QT6T w/Gantry Robot & Dead Length Chuck (2” cap)

- 1 Citizen L20 Swiss Lathe (¾” cap)

- 1 Mazak Nexus II 200-MSY Multi-Task w/Live Tooling (2⅝” cap)

CNC Milling Equipment

Our Vertical Milling equipment includes:

- 1 Fanuc Robo Drill CNC Milling Center

- 1 Fanuc Drill Mate CNC Milling Center

- 2 Kia V25P Dual Pallet Milling Center

- 1 Mazak 410A Milling Center (40” x 20” x 20”)

- 1 Mazak VTC-200B Milling Center w/Full 4th Axis (46″ x 28″ x 24″)

- 1 Mazak VTC-200C Milling Center w/Full 4th Axis (65″ x 28″ x 24″)

- 1 VCN-510C w/Full 4th Axis & Wireless Tool Presetter & Part Probing

- 1 Mazak Nexus II 200-MSY Multi-Task w/Live Tooling (2-⅝” cap)

CNC Prototyping & Support Equipment

Our CNC Prototyping and Support equipment include:

- 1 Southern Proto-Trak Lathe

- 1 Southern Proto-Trak Mill

- 1 Bridgeport manual mill

- 1 Mazak Hercules Engine Lathe

- 1 Mitsubishi FX10 Wire EDM

- 1 Cincinnati Monoset Drill/Reamer Grinder

- 4 Do-All Surface & Tool Grinders